Aluminium Finishes Explained: Bead Blasting, Graining, Paint & Powder with Presto Engineering

Aluminium is one of the most versatile materials in manufacturing. It’s strong, lightweight, and corrosion-resistant. But the right finish is key—both for performance and looks.

At Presto Engineering, we offer expert advice and finishing services to help your parts do their job and stand out.

Why Finish Aluminium?

- Protection: Guard against scratches, wear, and weather.

- Appearance: Tailor colour and texture to your brand or design.

- Grip & Feel: From polished handles to matte control panels, finishes change the user experience.

- Prep for Coating: Pre-finishing like bead blasting ensures coatings stick properly.

Finish Options at a Glance

Bead Blasting:

A uniform, matte finish created with air-blown fine media. Ideal for prep or a sleek industrial look.

Graining (Brushing):

Stylish, linear texture often used in visible panels or enclosures. Helps achieve a uniform finish.

Wet Painting:

Great for complex shapes or heat-sensitive materials. Offers virtually unlimited colour and gloss options.

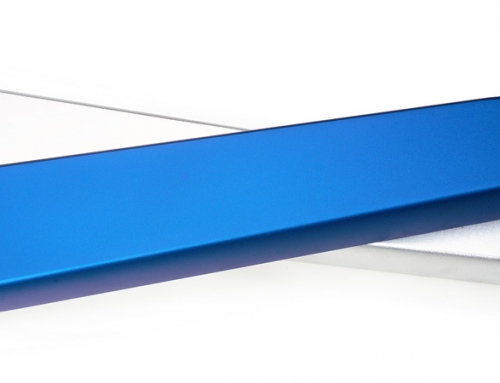

Powder Coating:

Durable, vibrant, and chip-resistant. Perfect for outdoor or high-use parts.

How to Choose?

- Environment: Harsh settings? Powder coat is a winner.

- Aesthetics: After a brushed or matte look? Try graining or bead blasting.

- Material & Shape: Delicate parts? Wet paint may suit better.

Every project has different needs—and Presto Engineering is here to guide you through the options.

👉 For expert finishing advice and high-quality results, call Presto Engineering today. Ask how Presto Engineering can help perfect your aluminium parts.